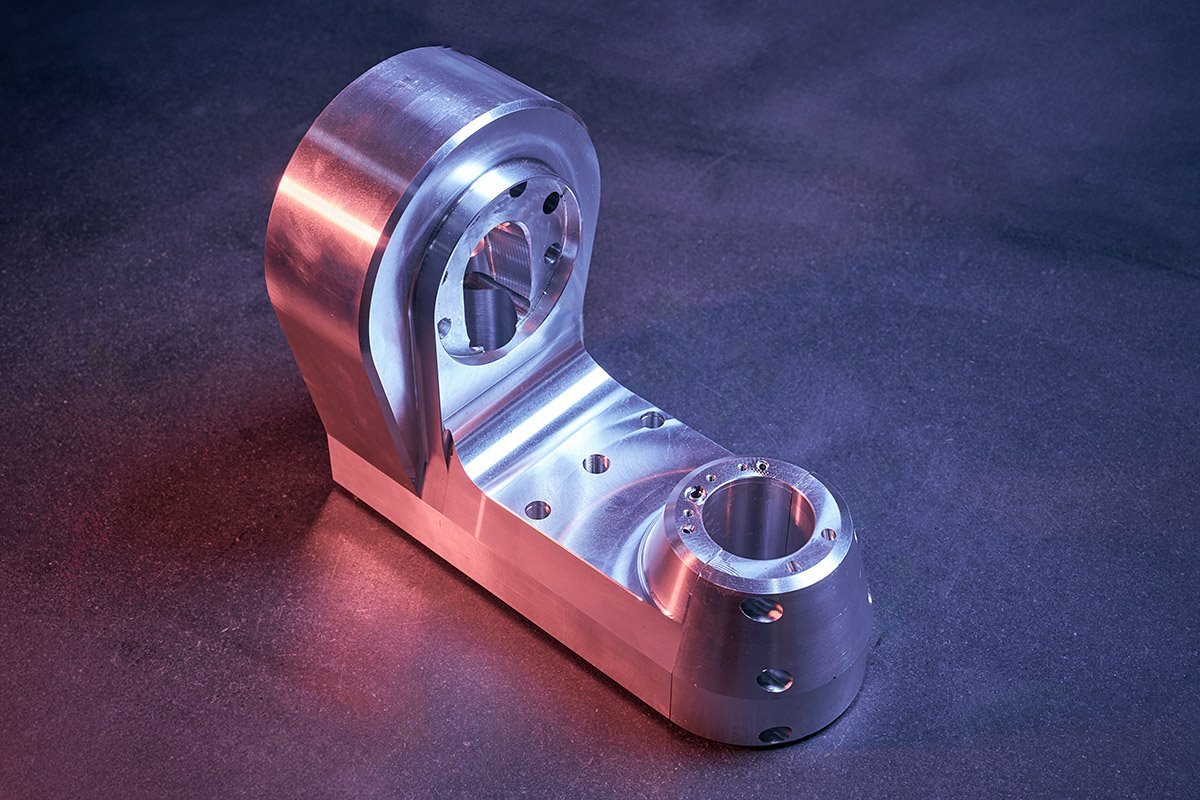

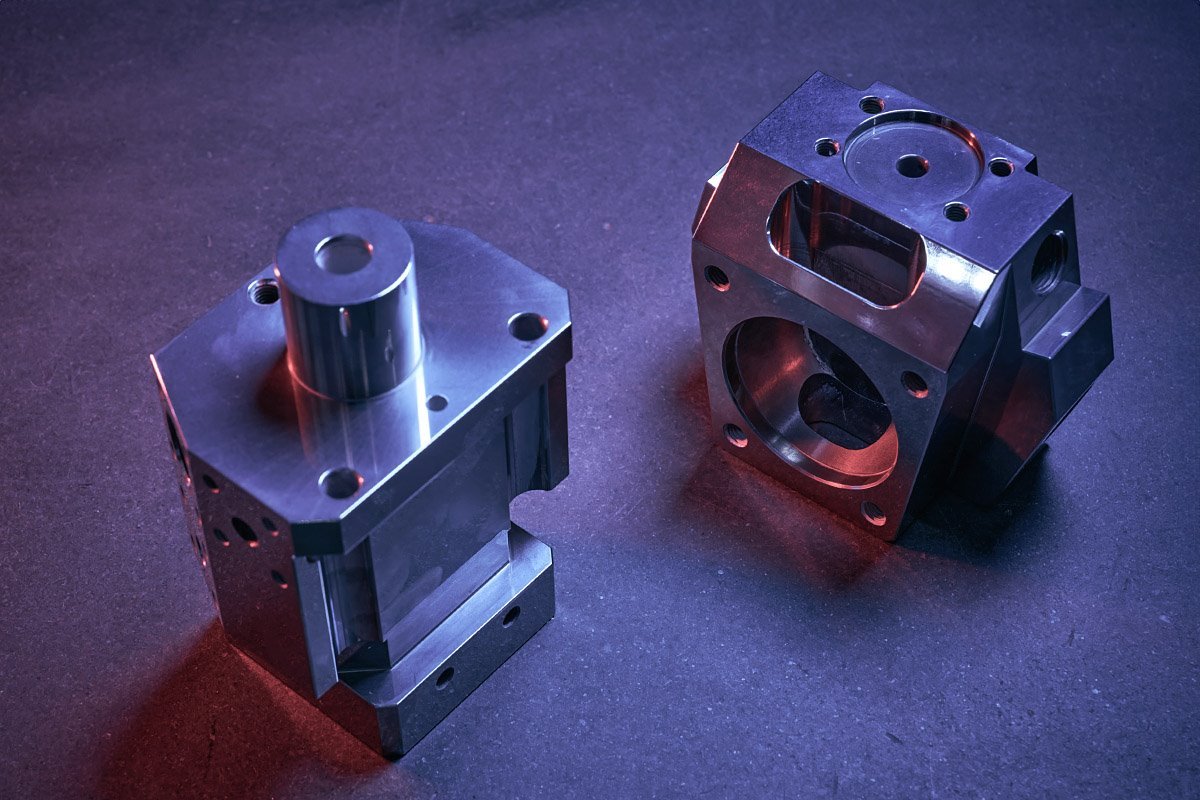

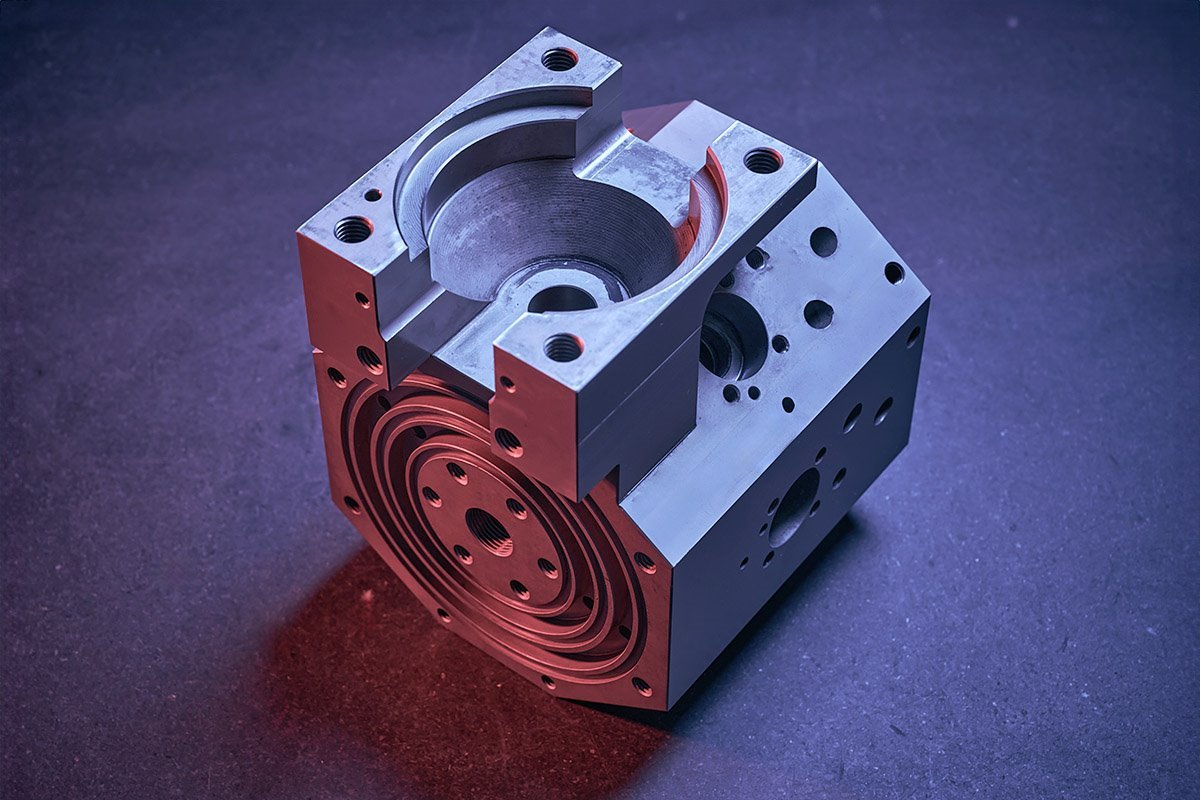

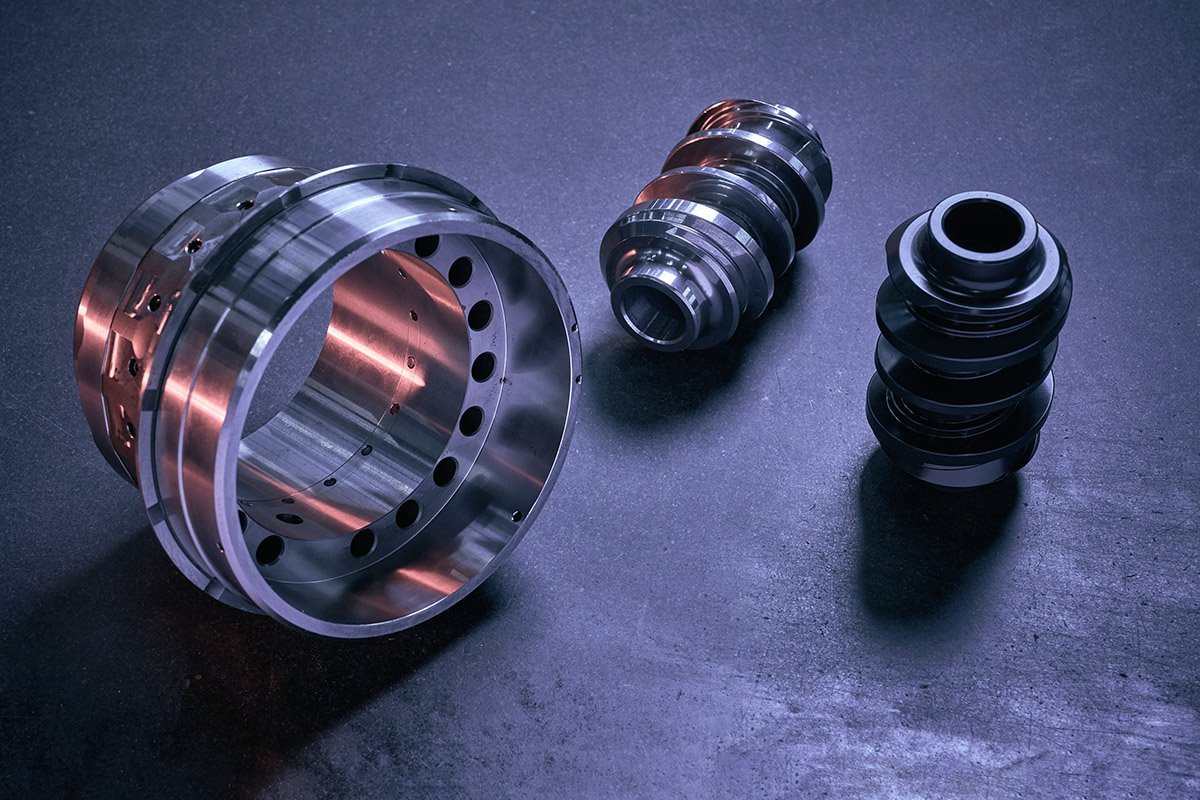

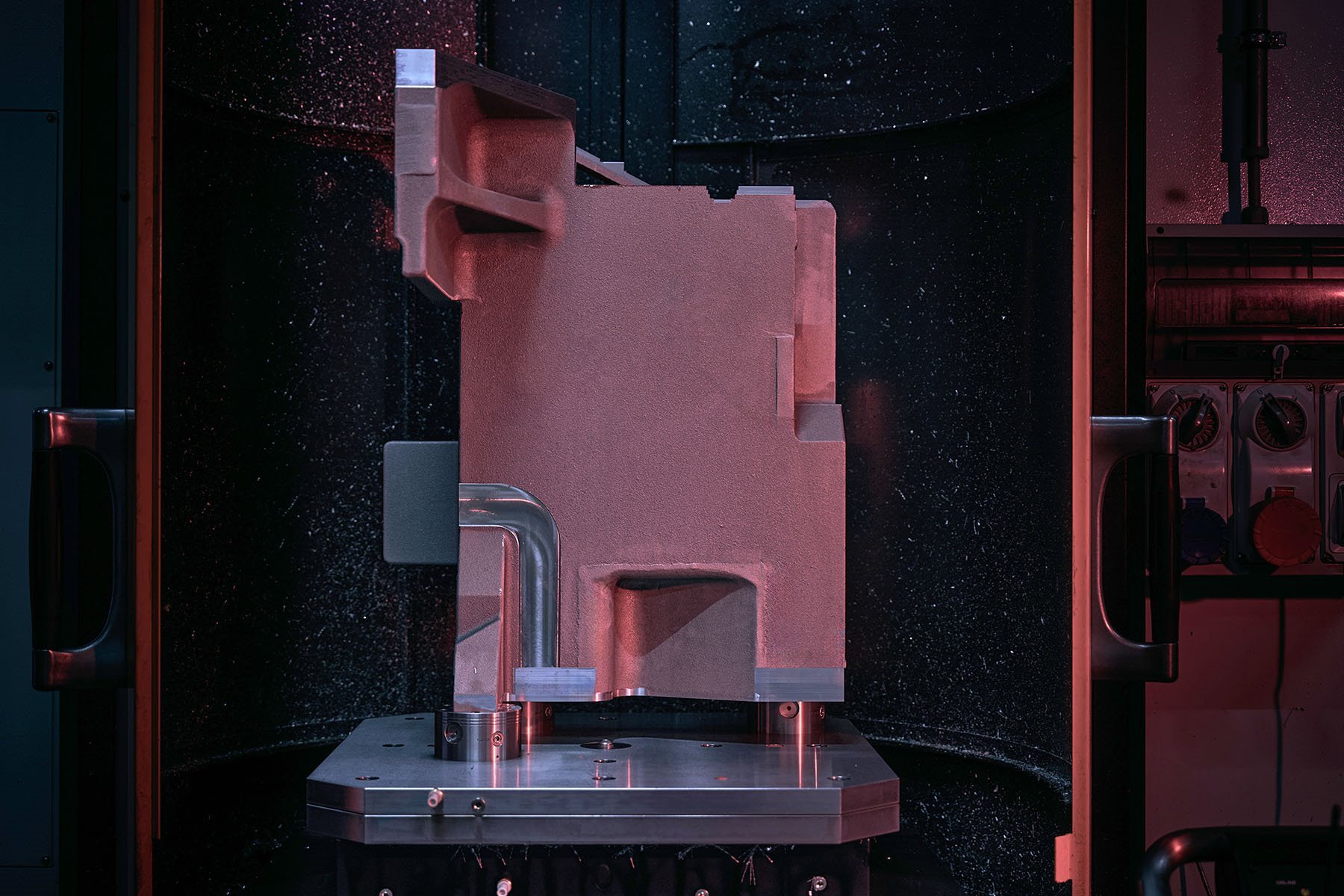

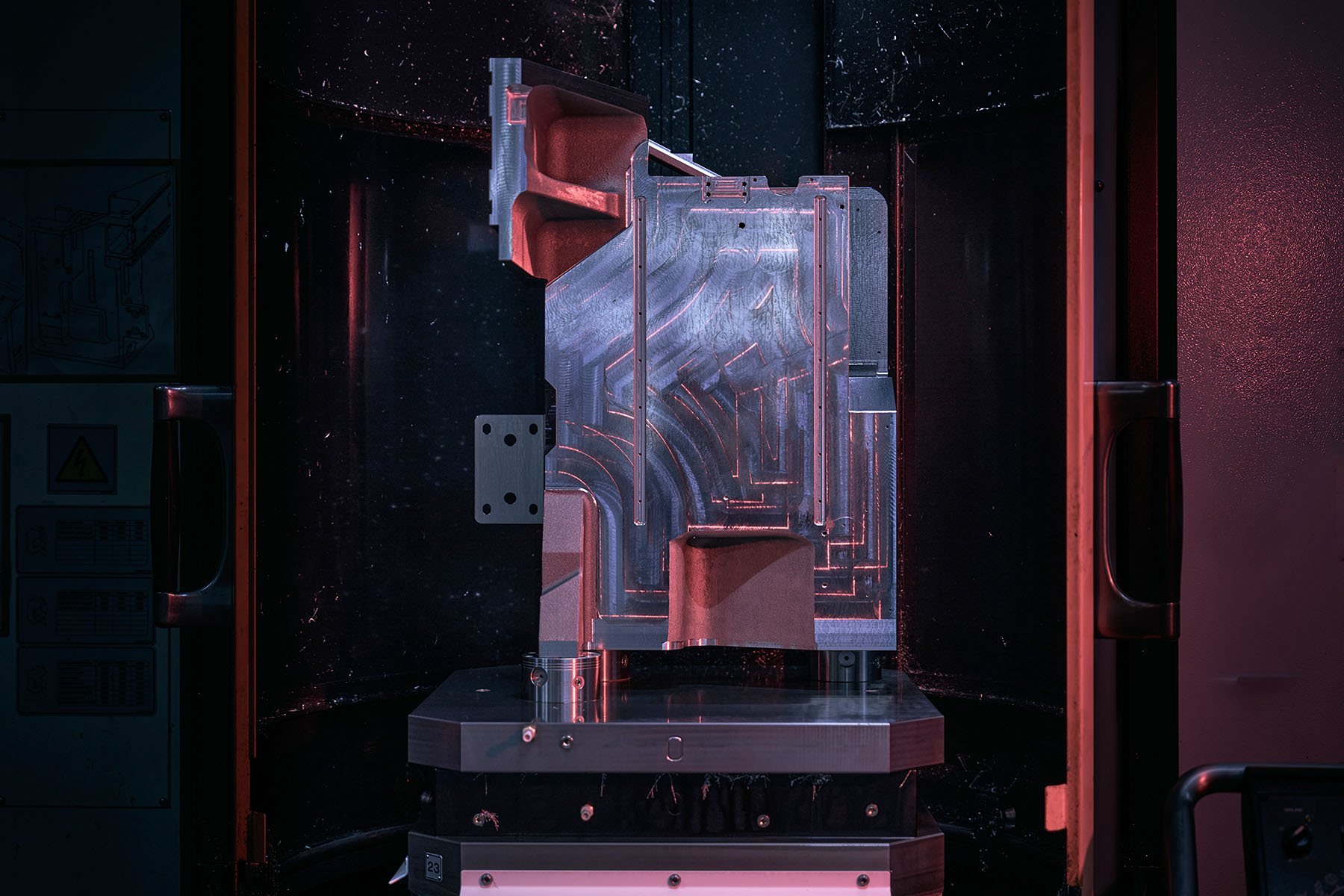

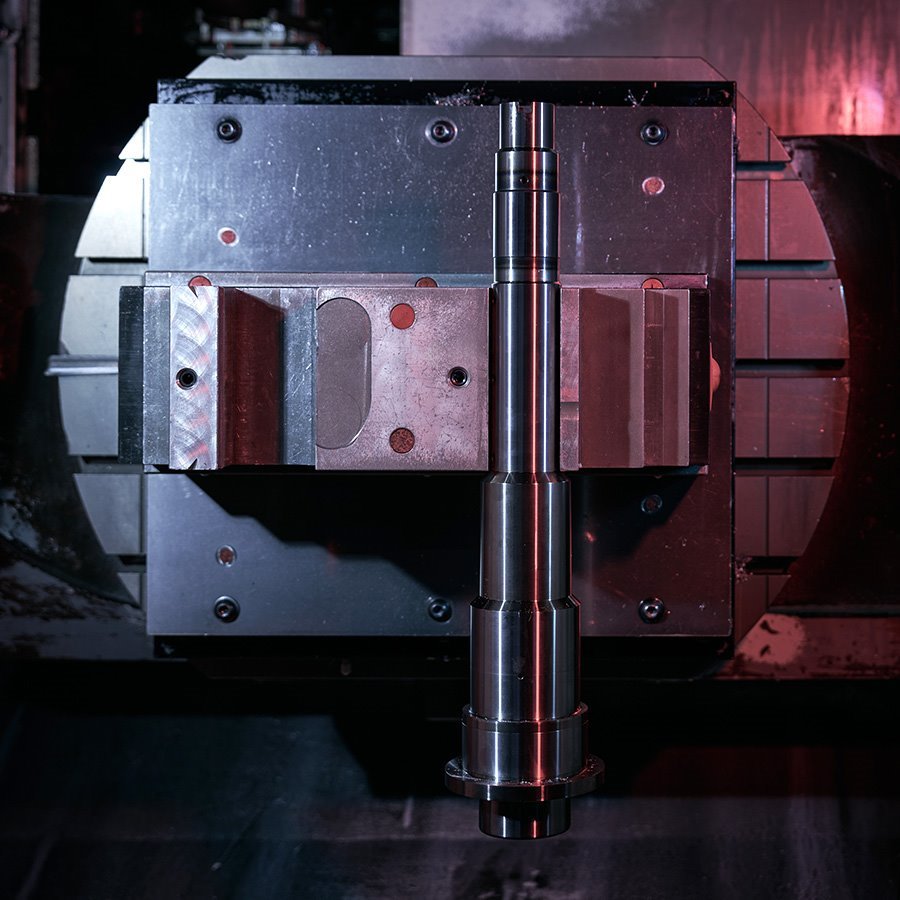

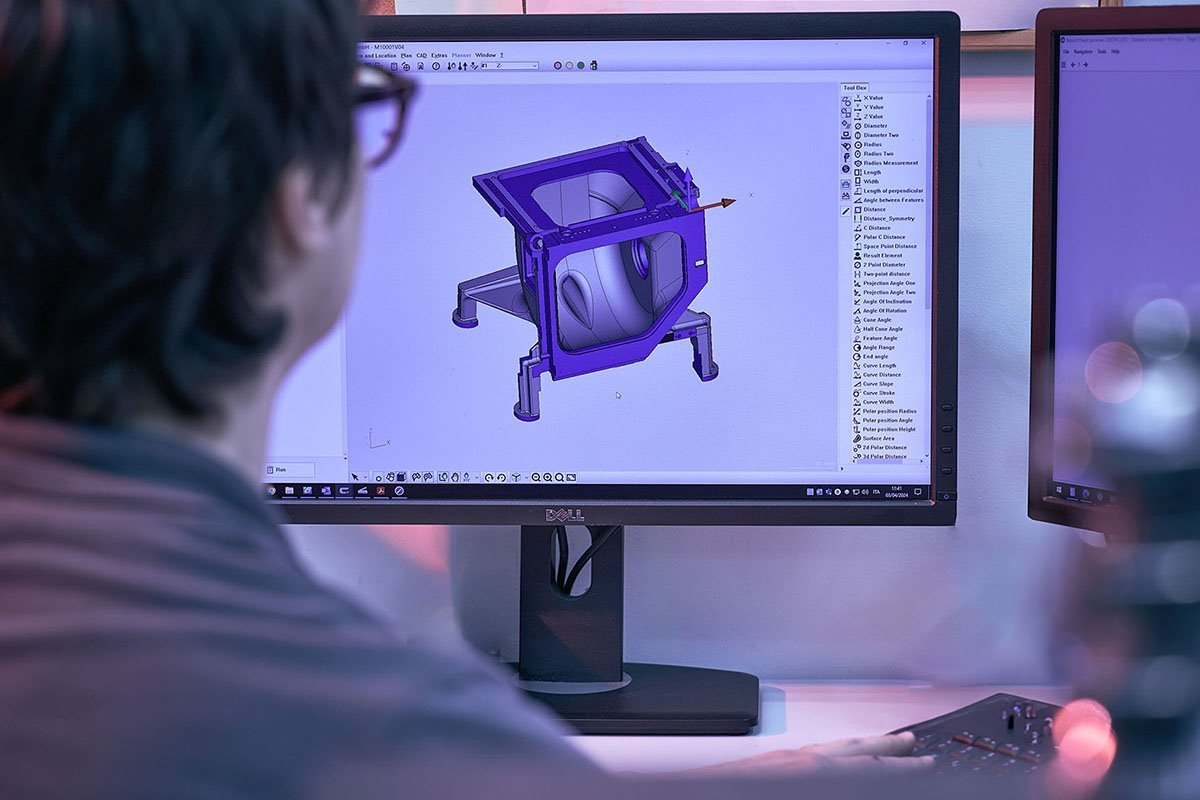

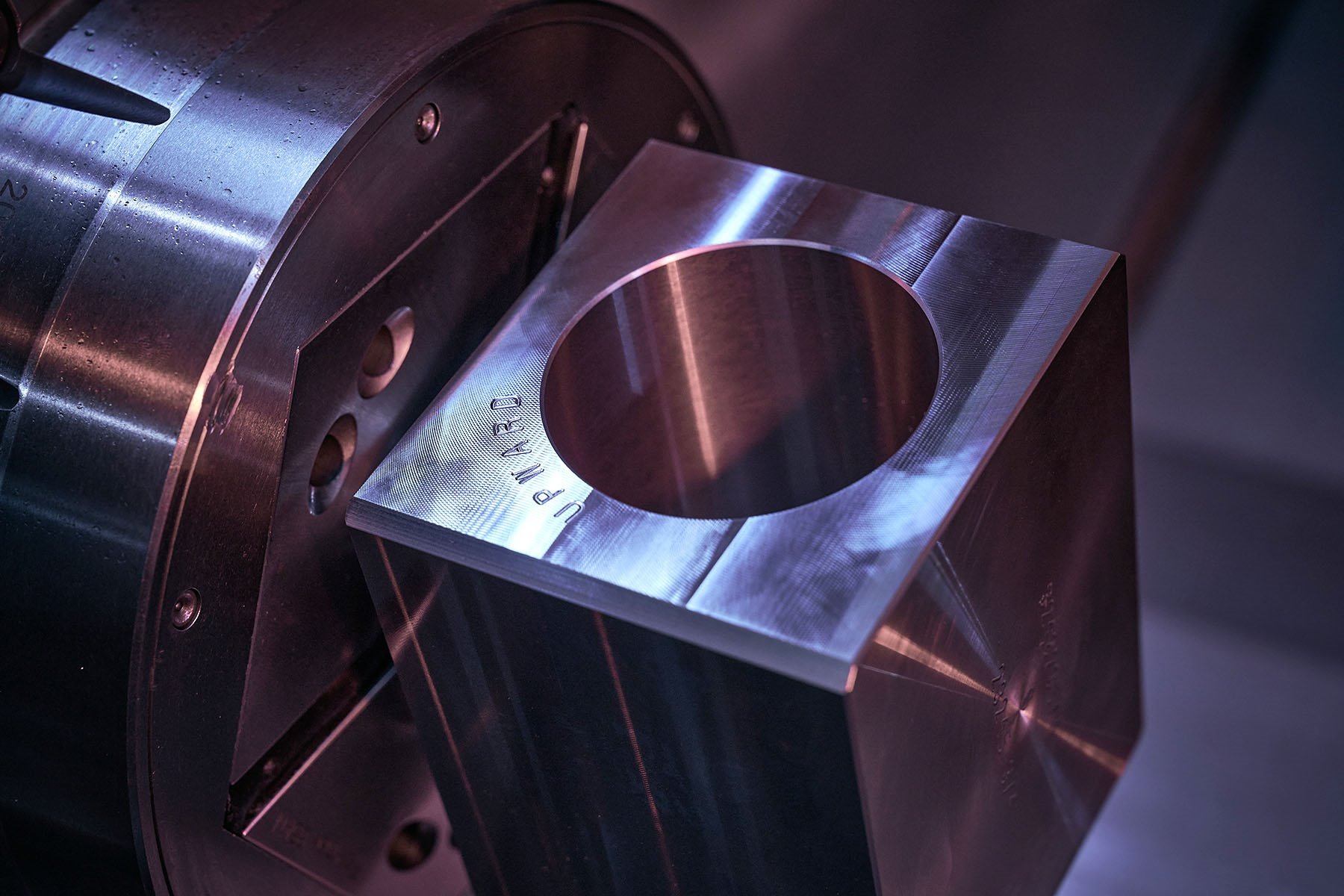

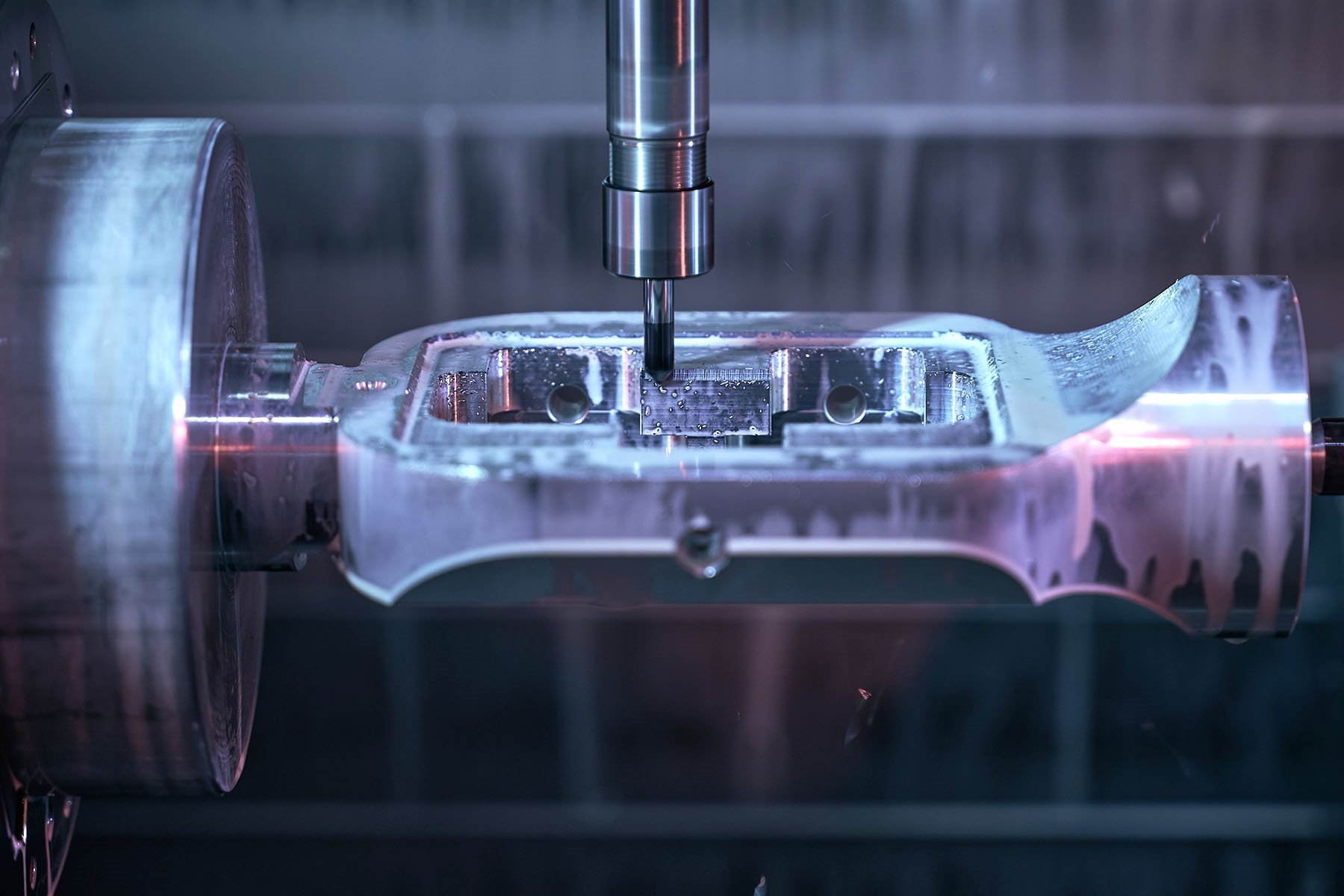

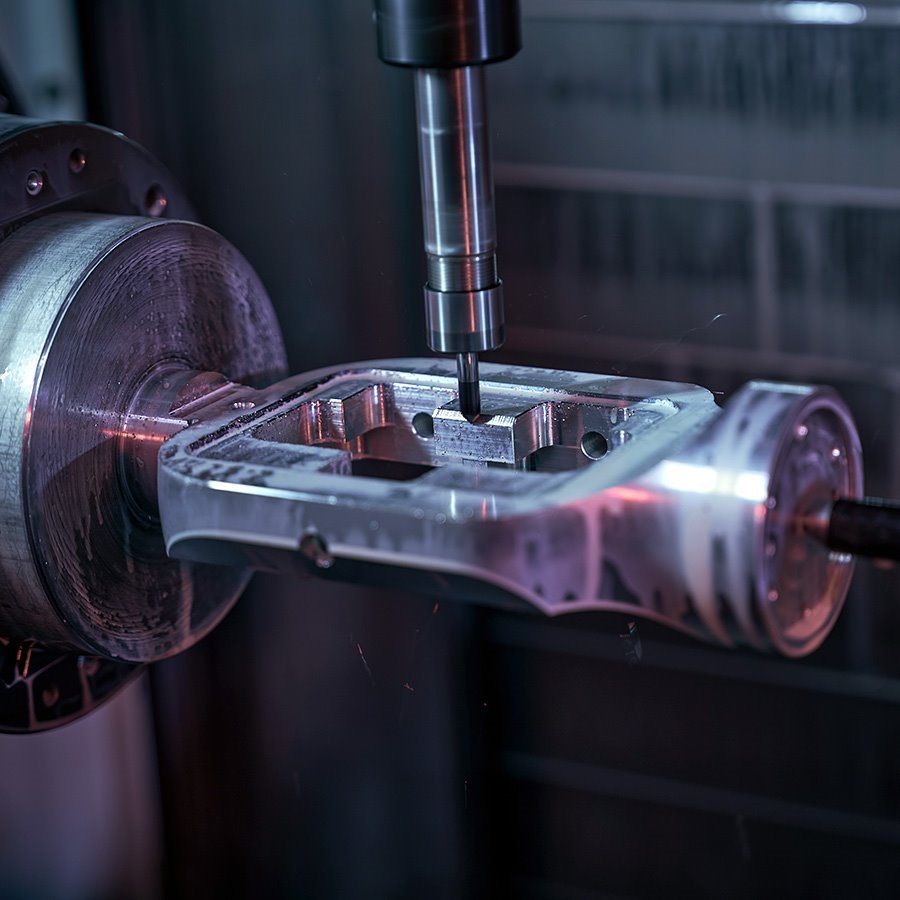

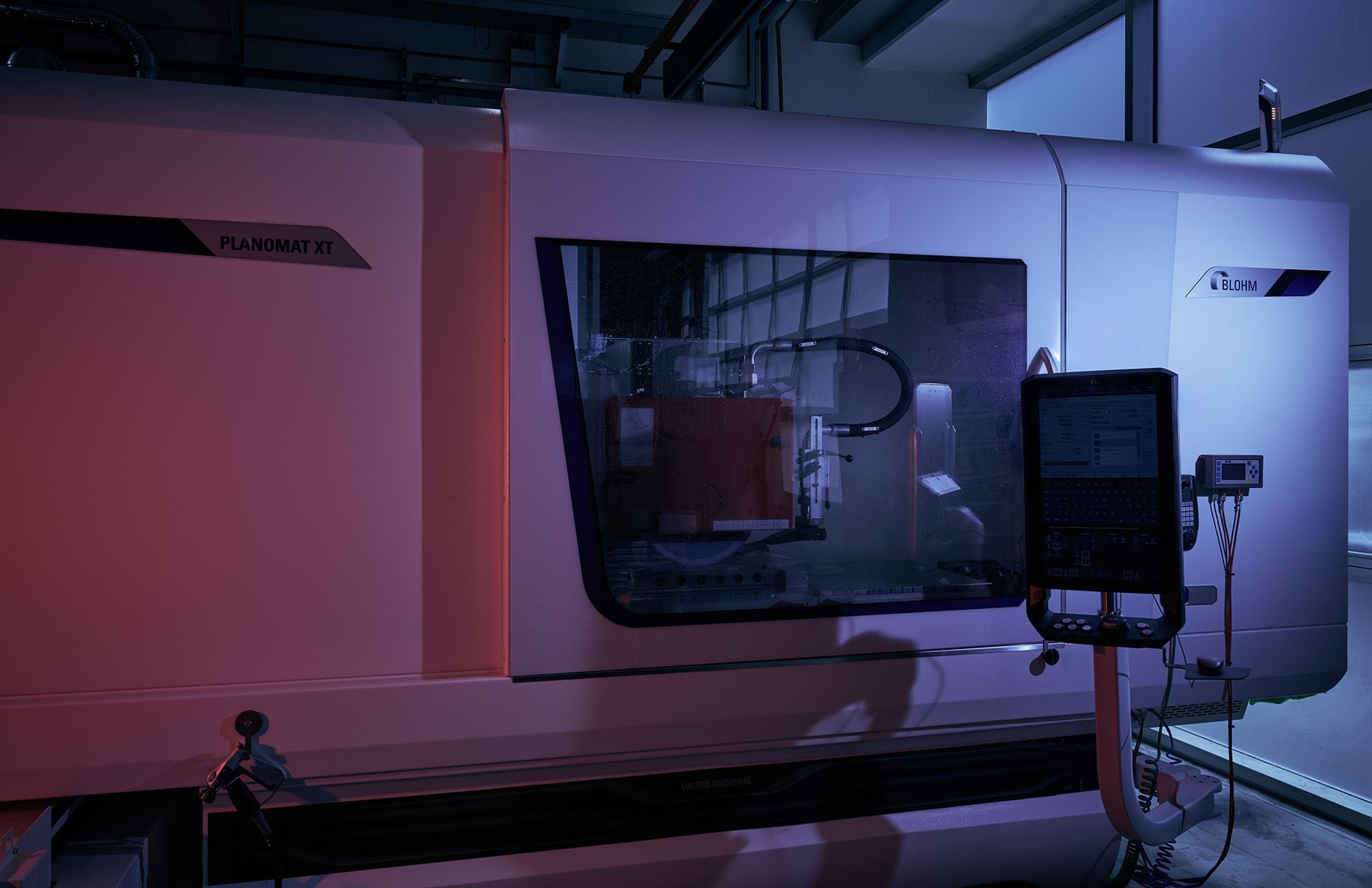

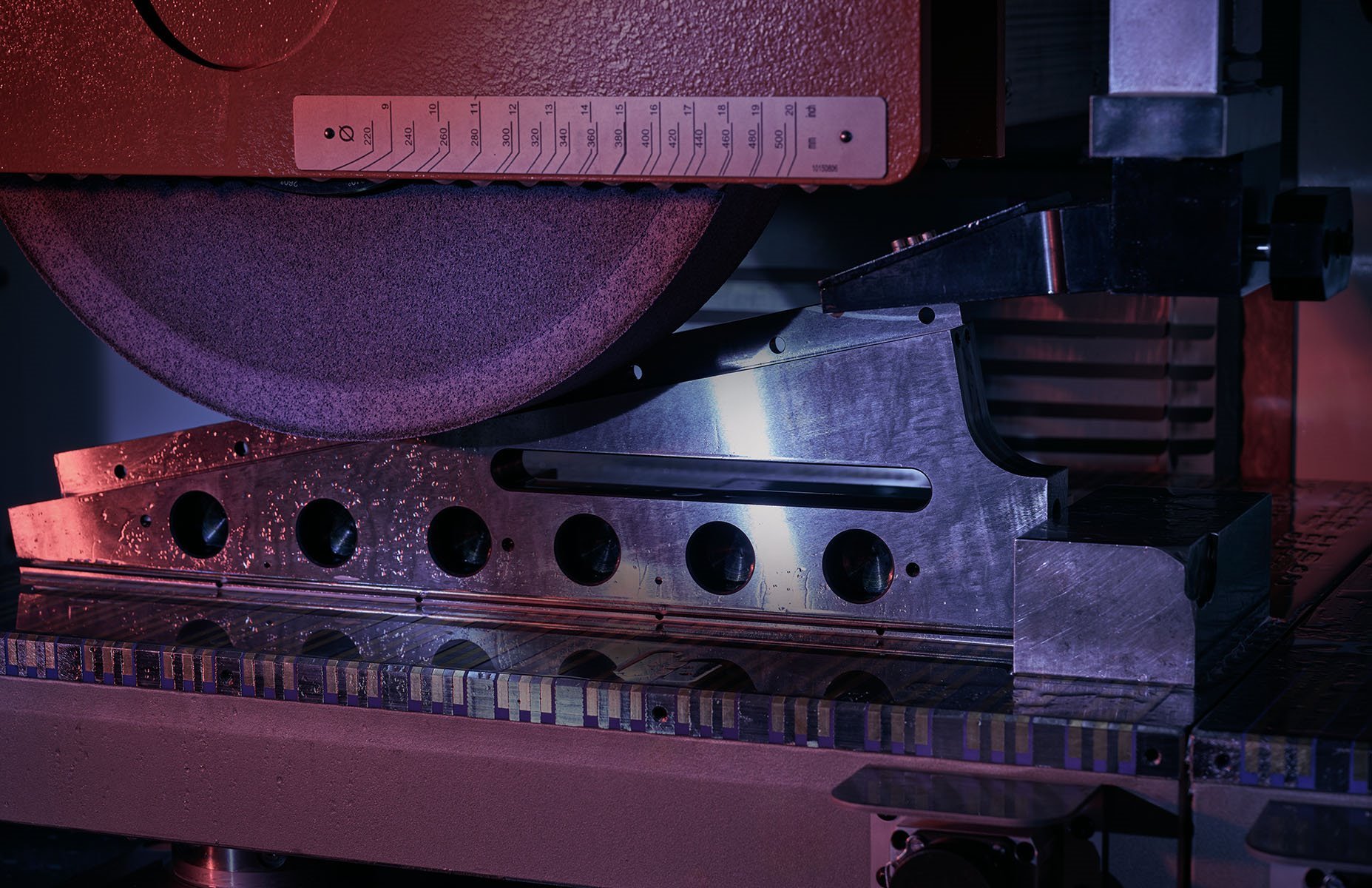

Milling

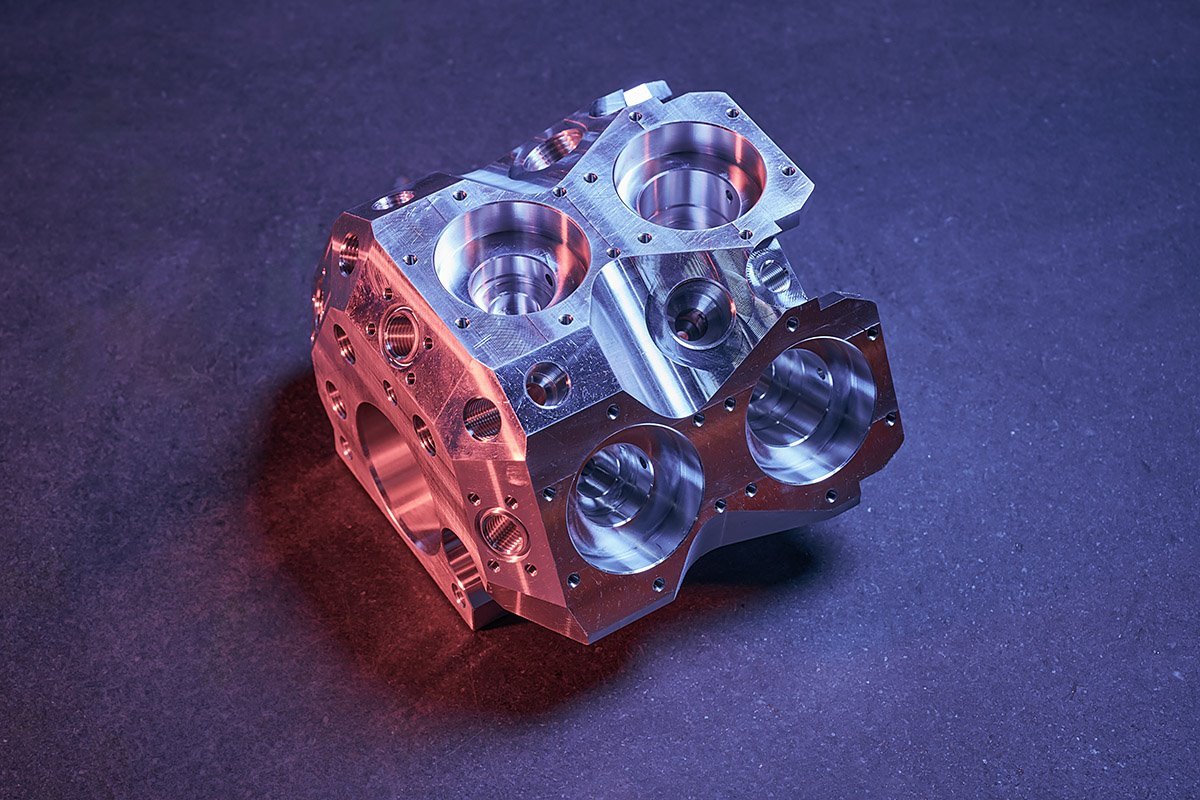

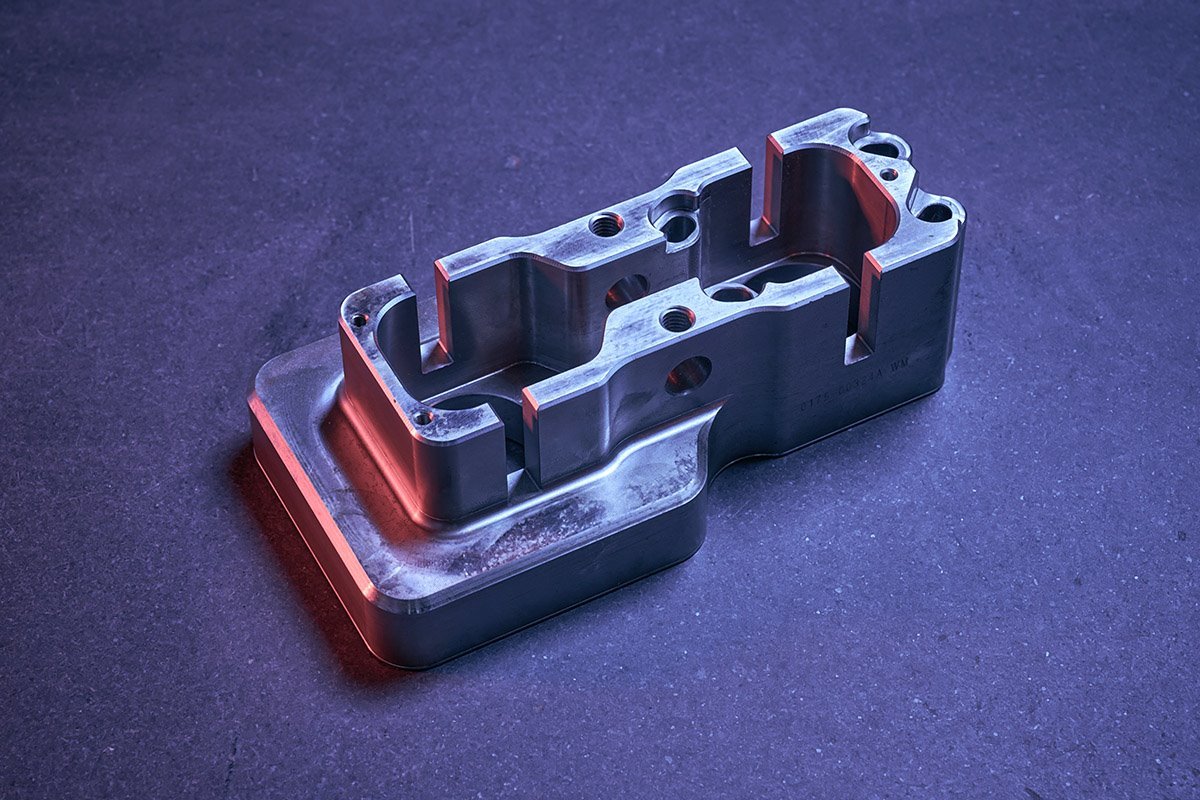

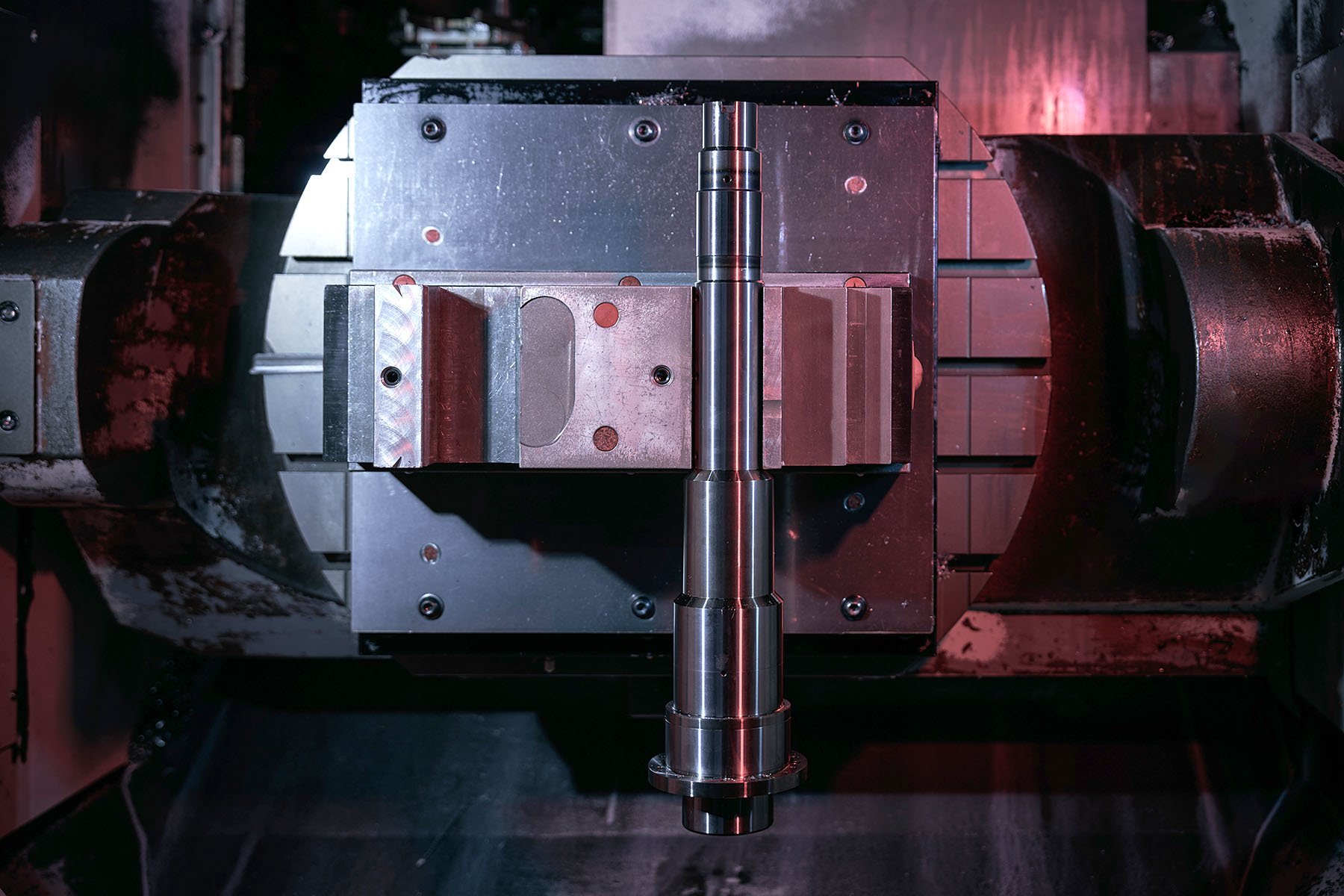

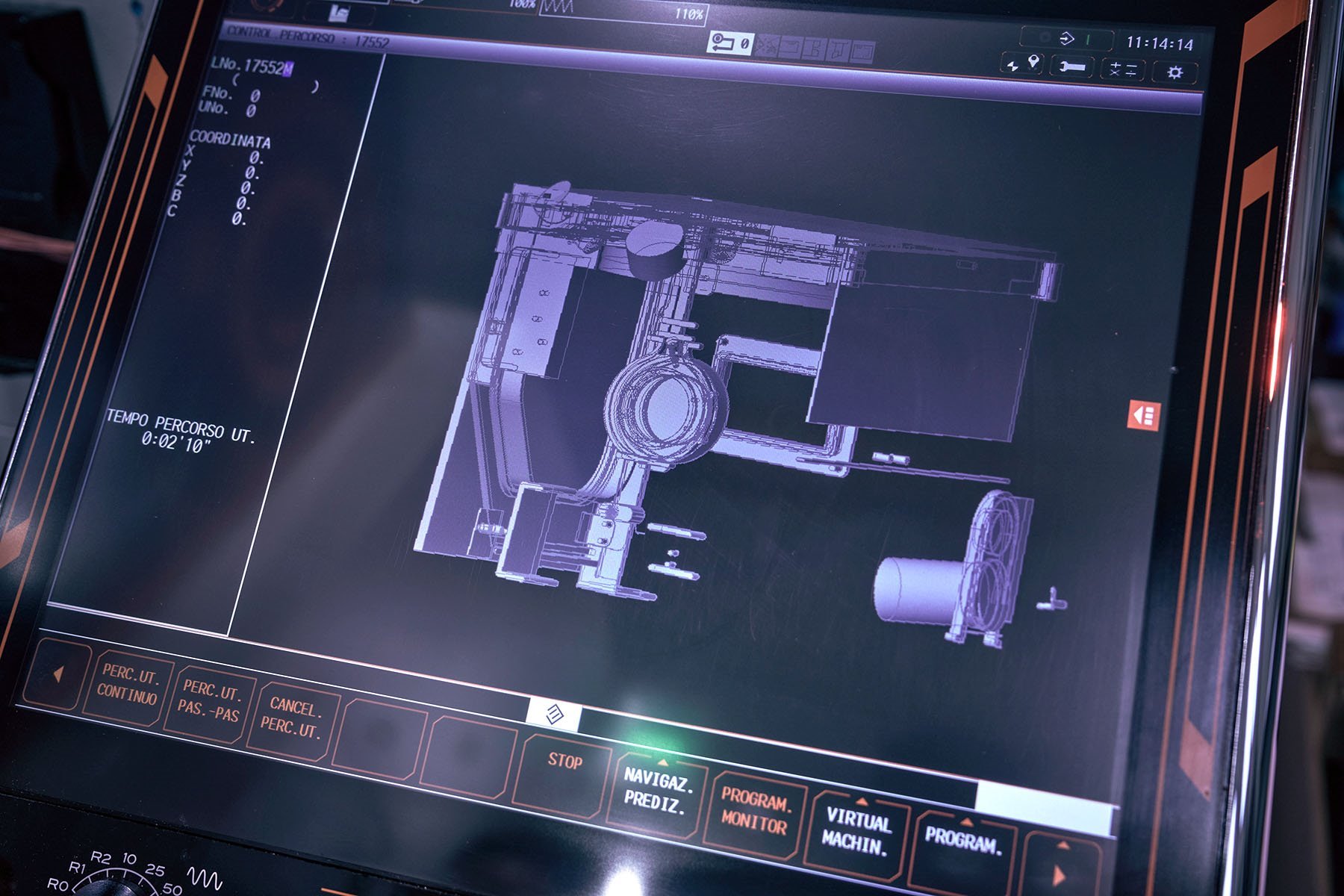

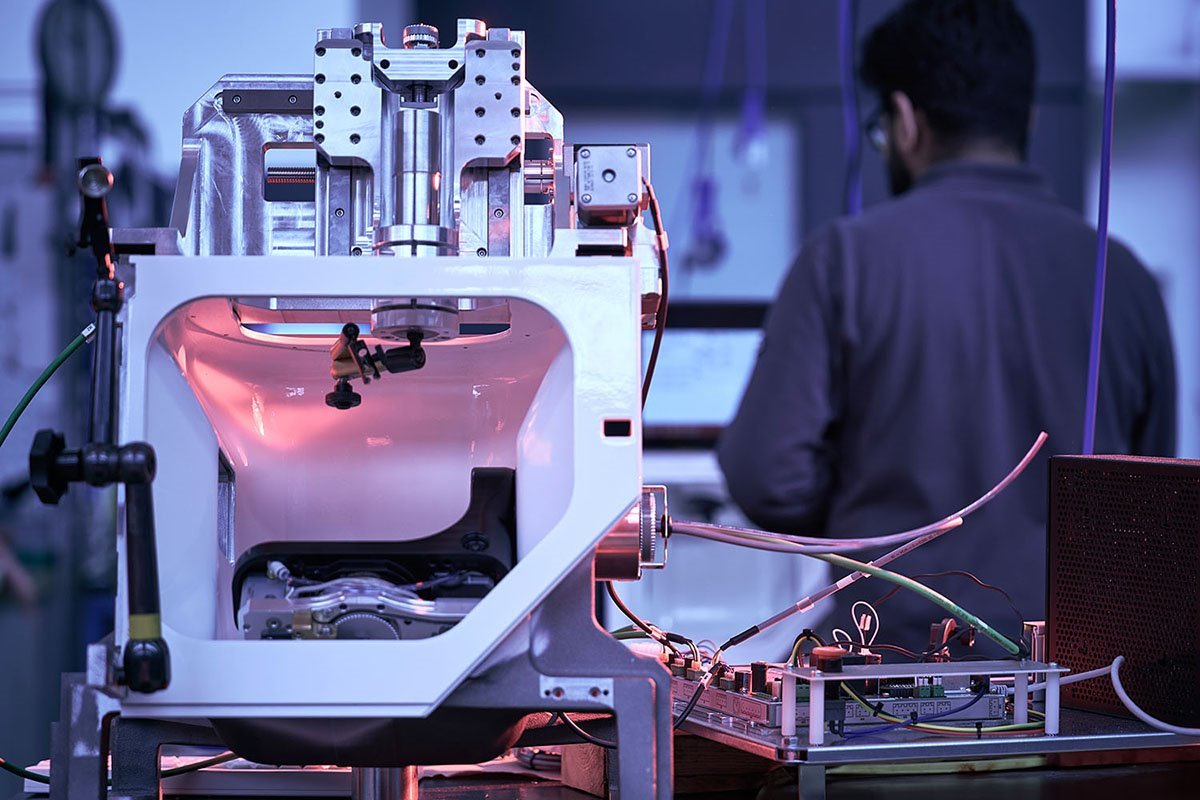

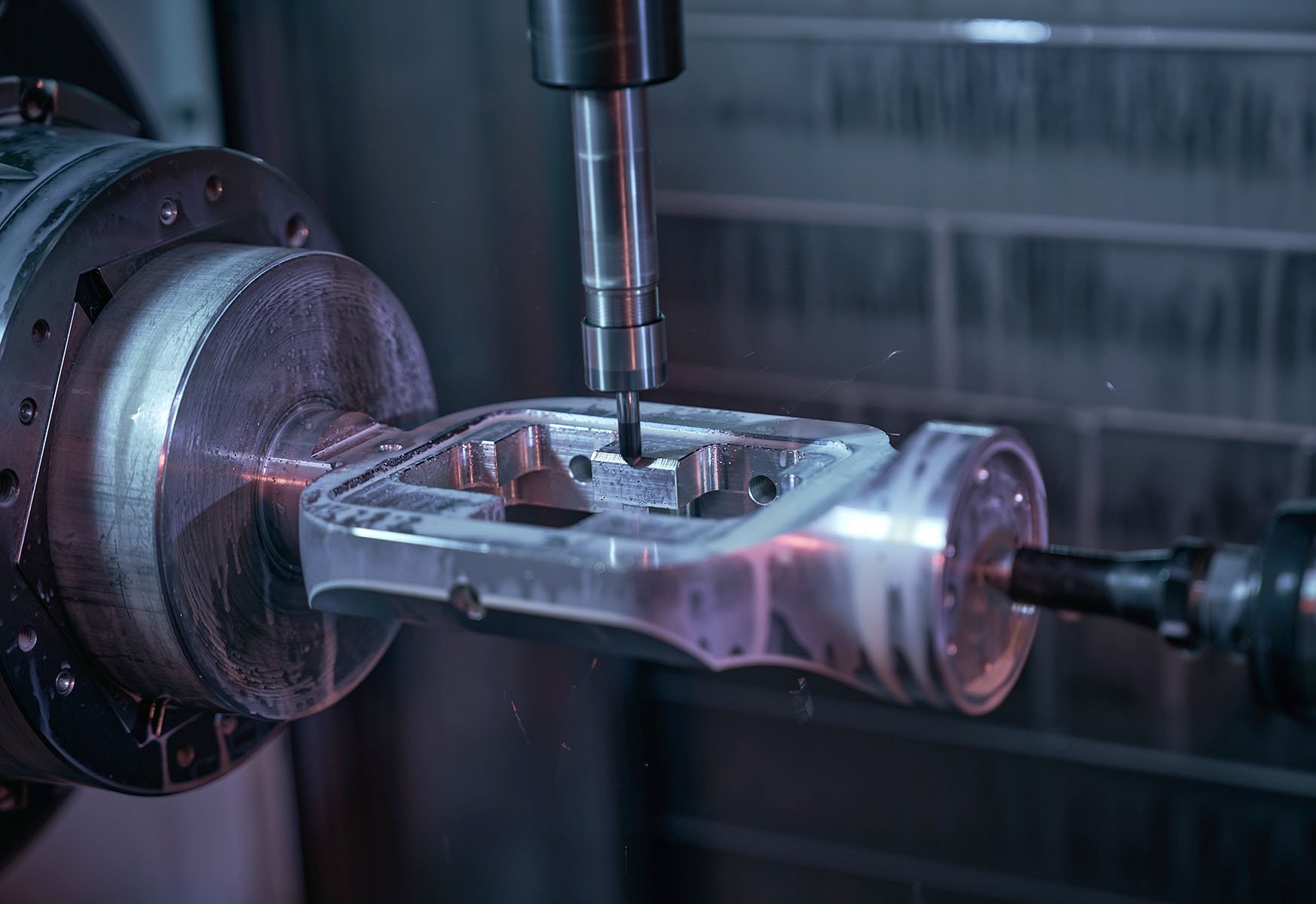

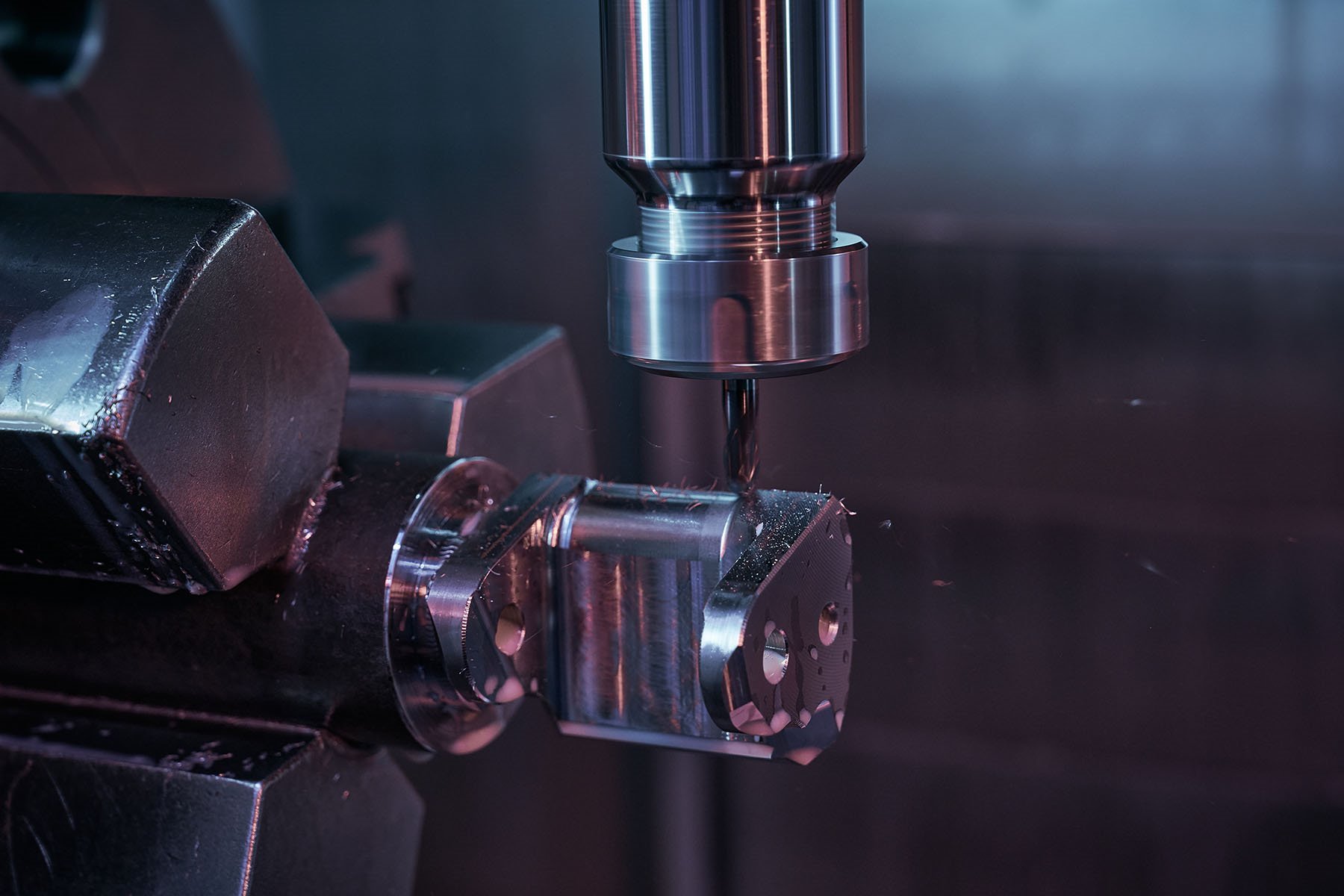

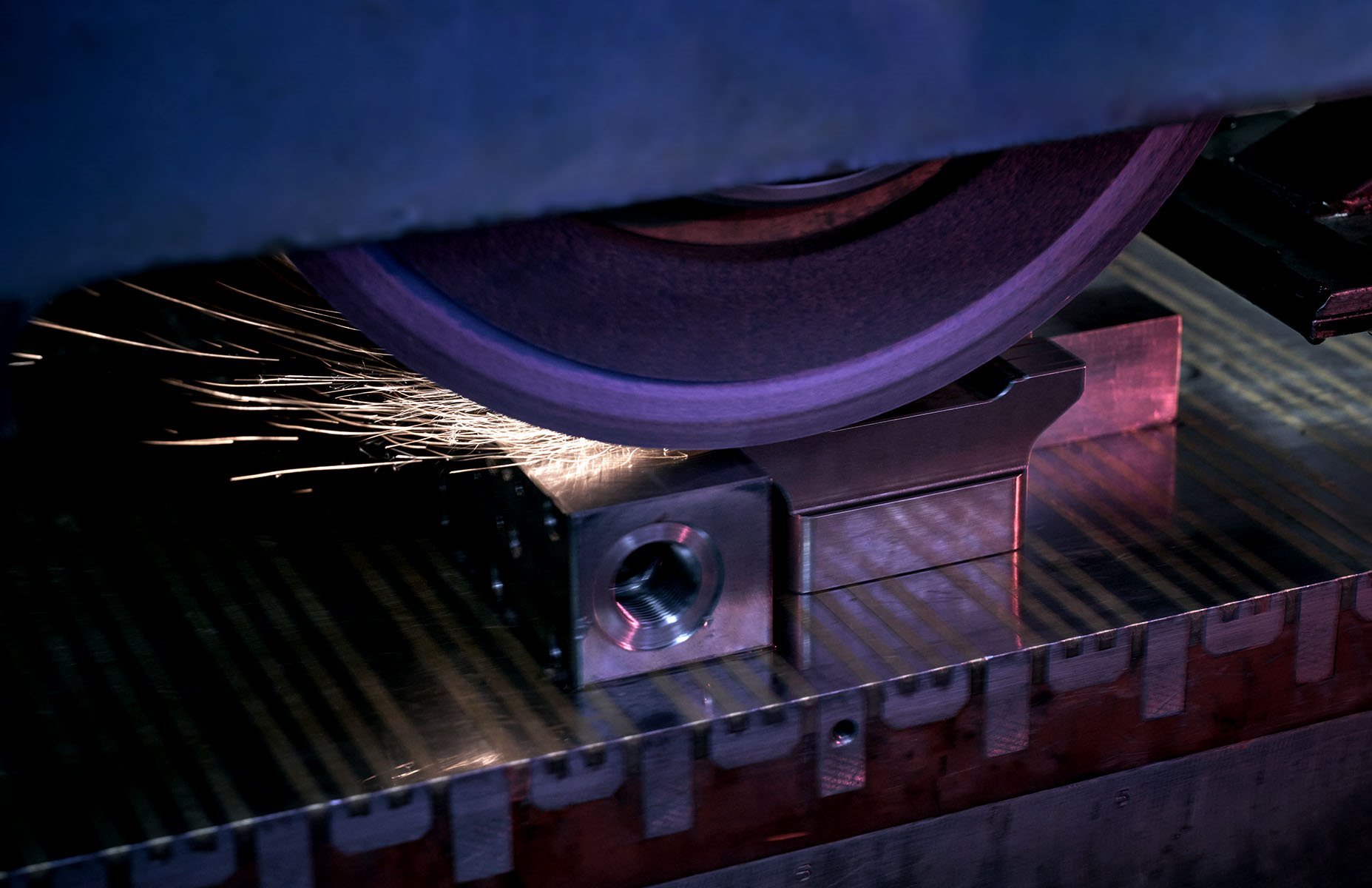

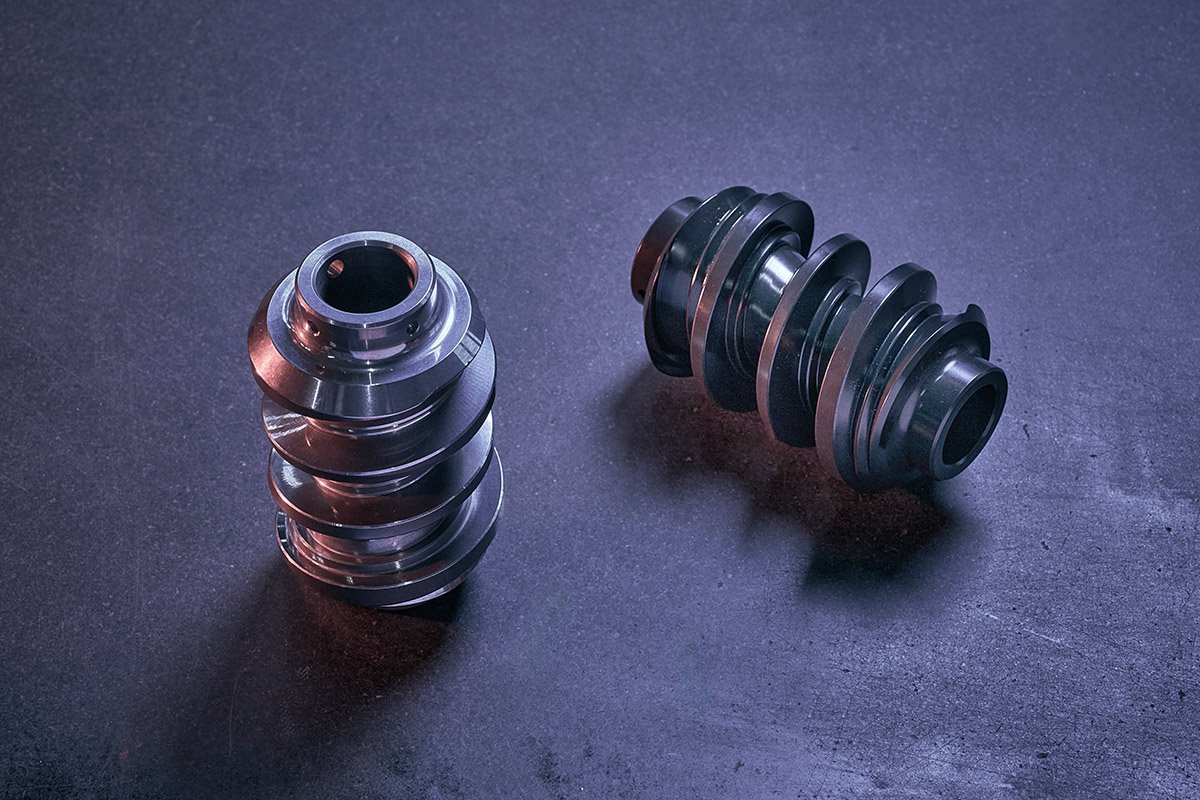

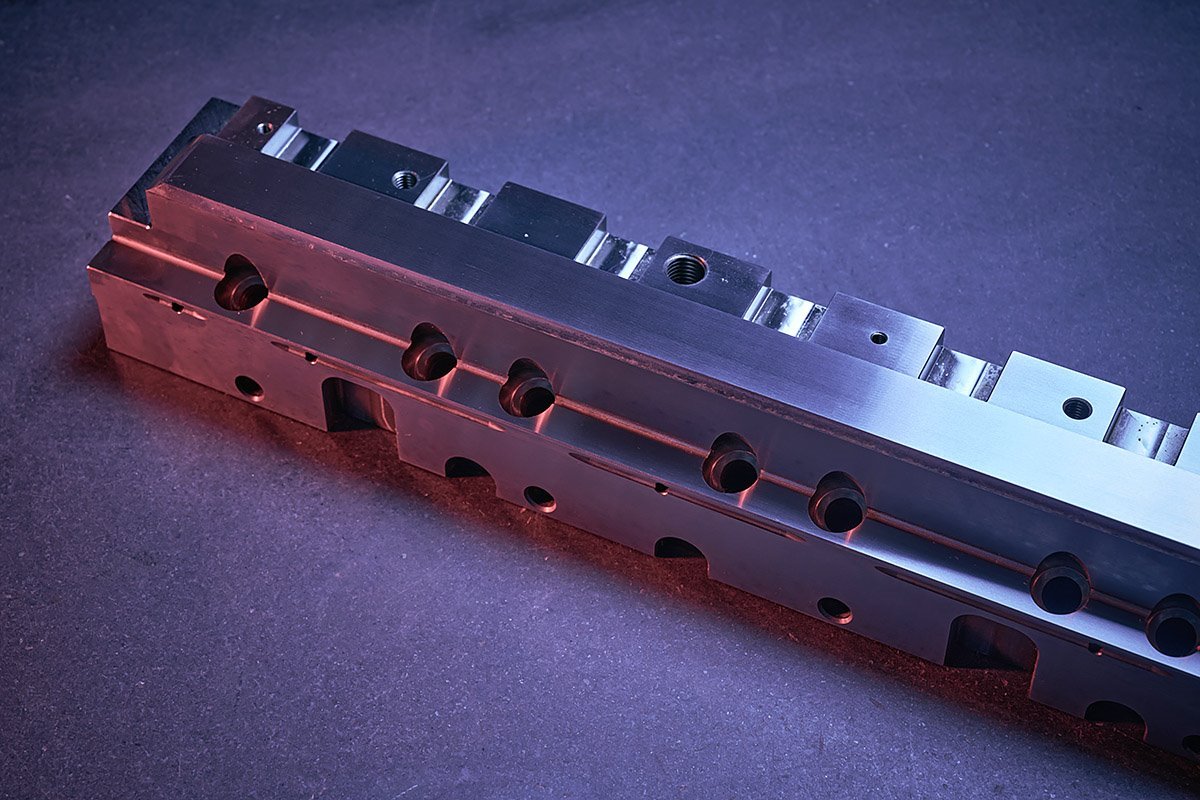

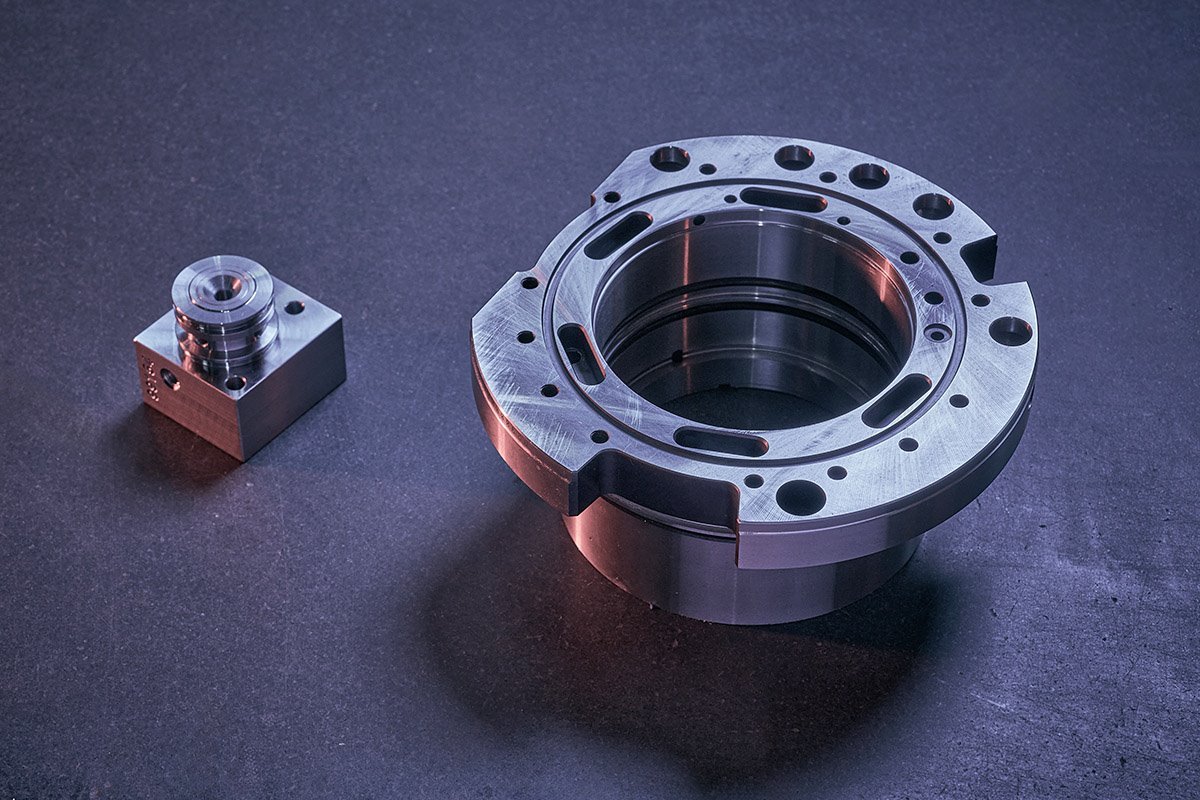

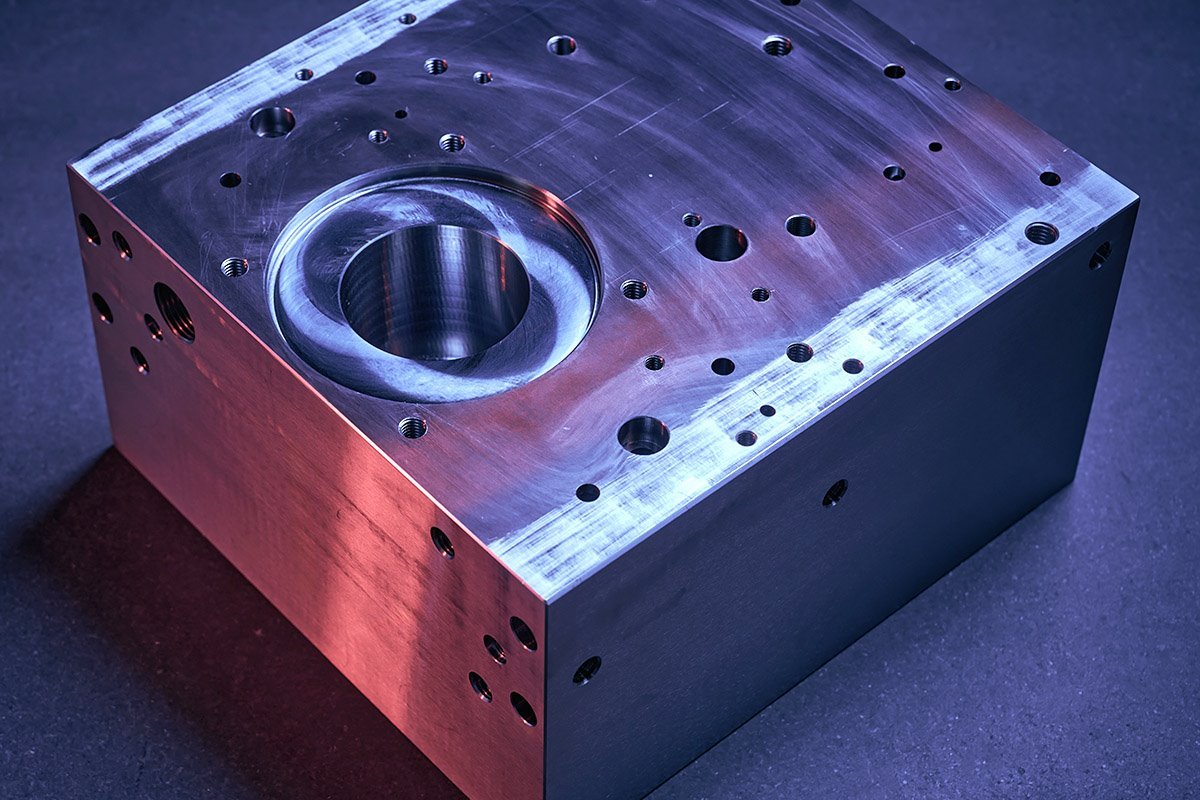

Milling is an indispensable process for the production of precision and quality mechanical components. The strong partnership with Mazak, a leader in the production of tool machines and equipment for the metal industry, allows us to perform very special milling operations and produce components of various sizes and complexity. Mazak machining centres are known worldwide for their precision, reliability and advanced technology in metal working.

· Milling on three-axis machining centres with a stroke of up to 3000.

· Milling on four and five-axis machining centres, positioned or continuous.

· Quick set up thanks to modular and dedicated equipment.

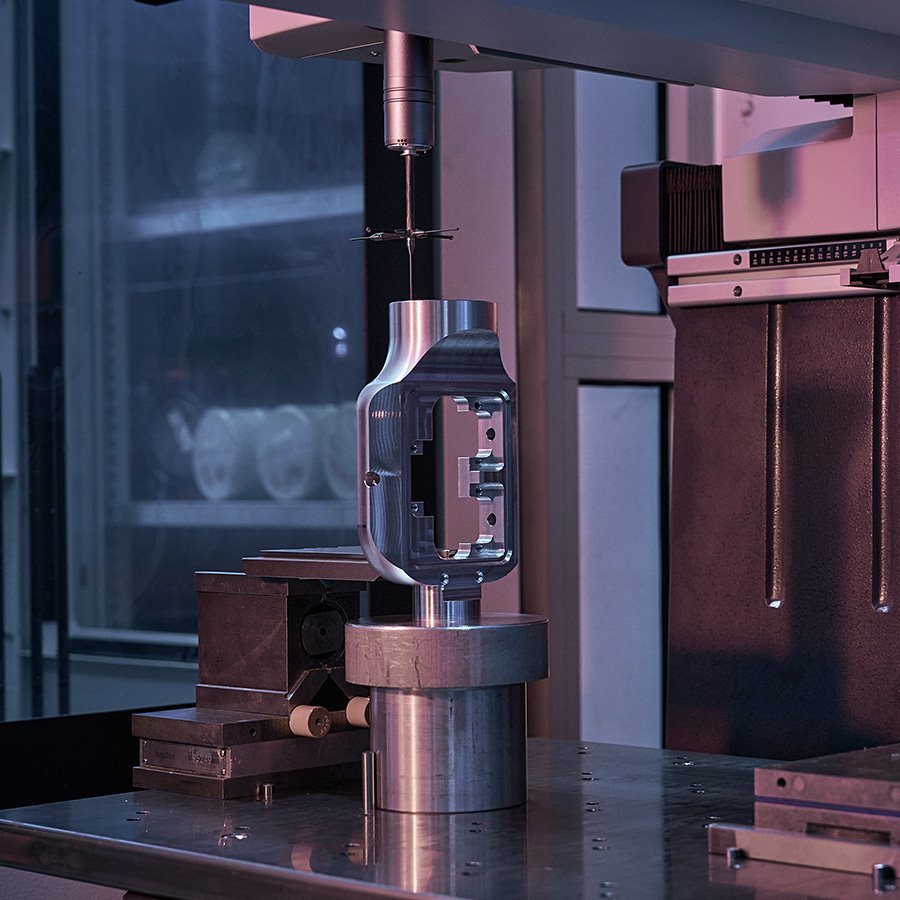

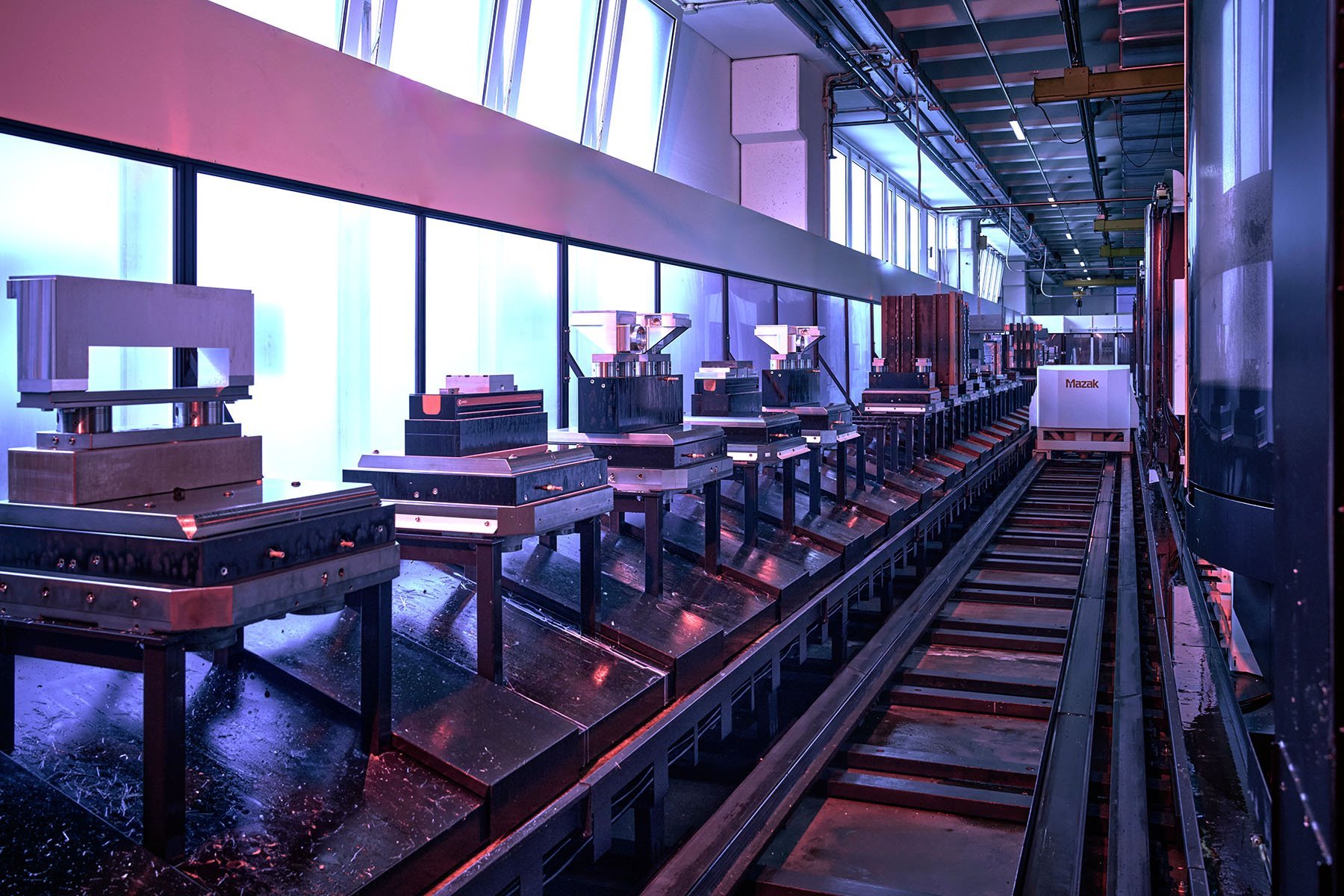

· Three five-axis centres with robotic power using the palletech system (FMS).

· Working area: X 1425 , Y 1050 , Z 1050 , C 360°, B +30° -120°.

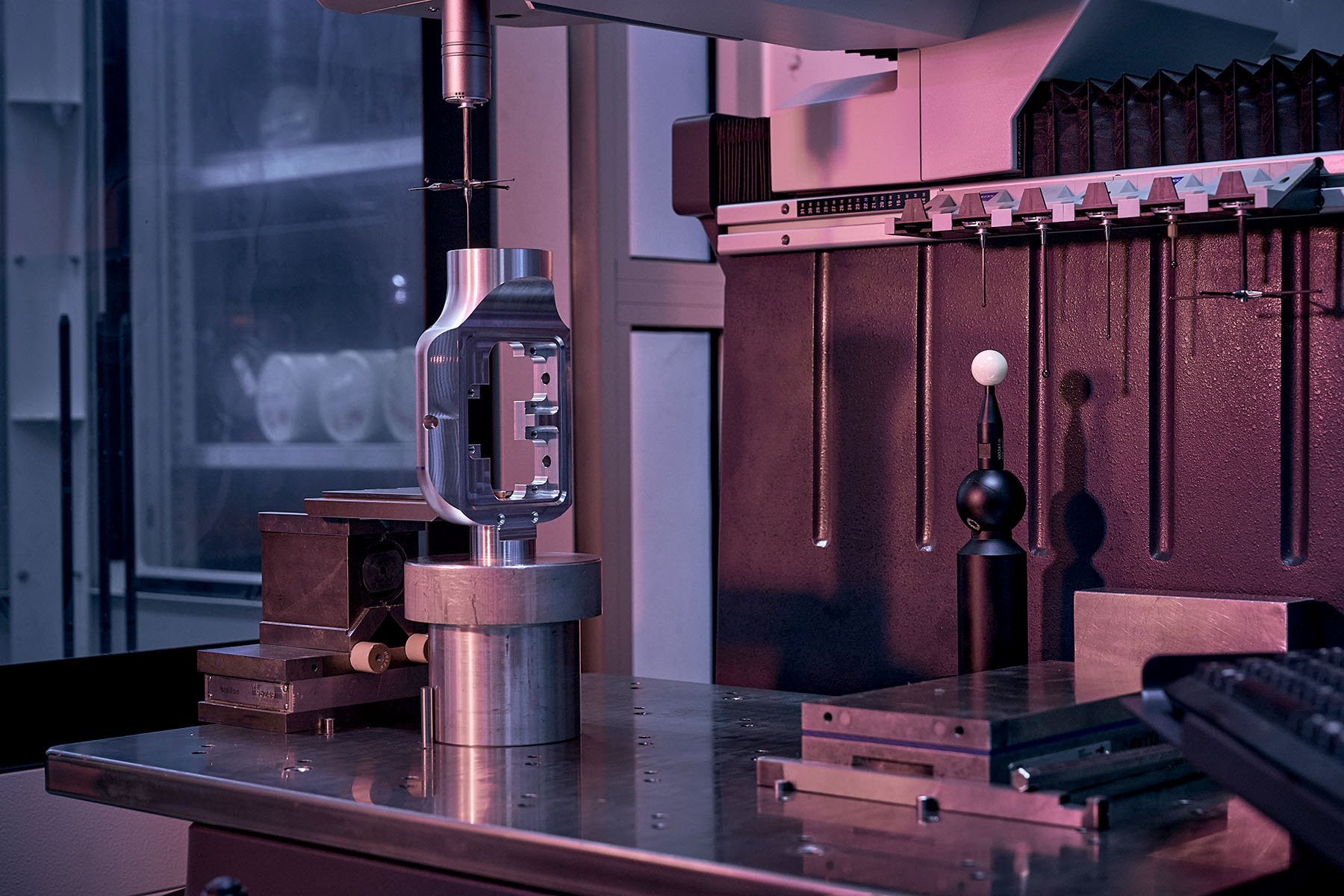

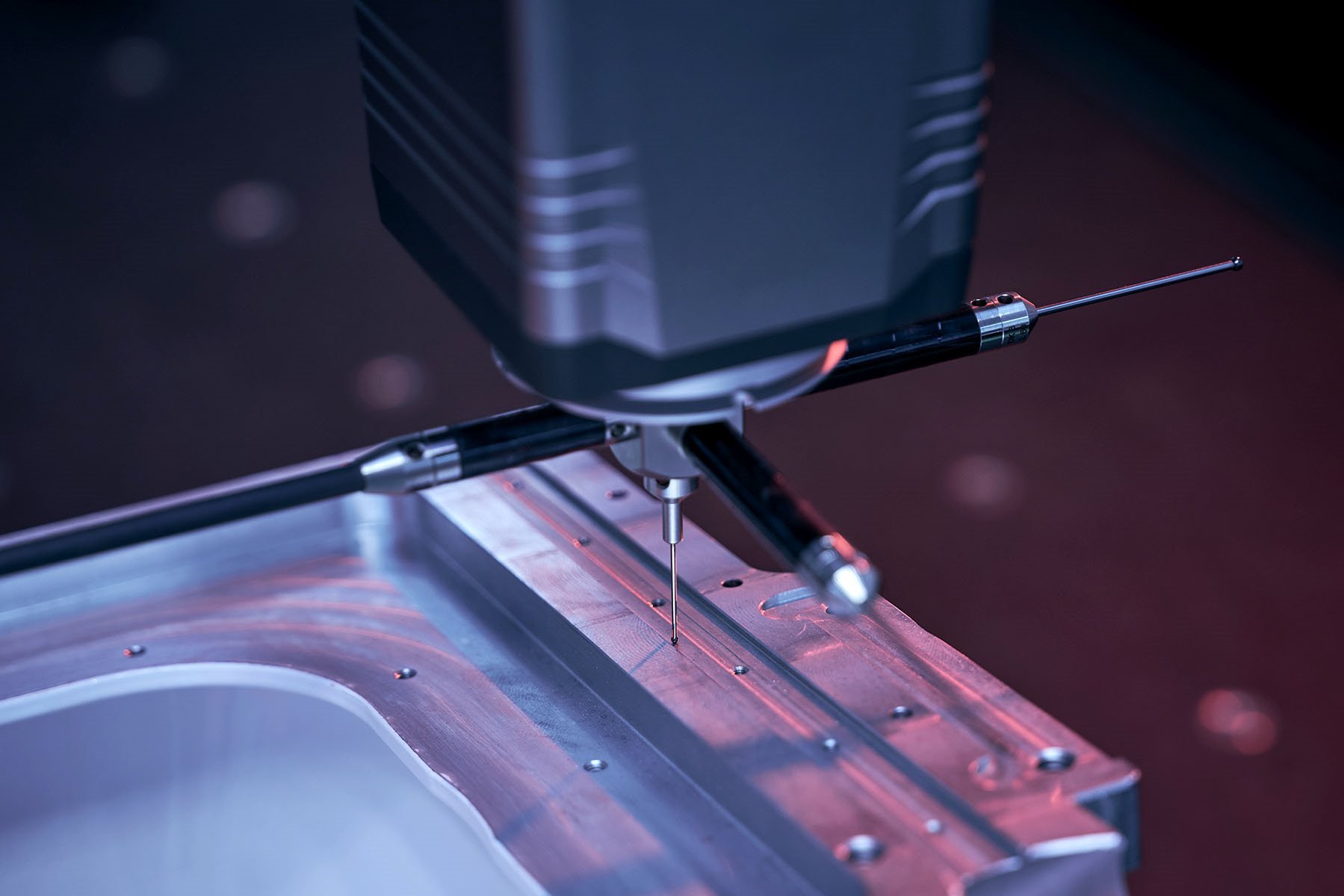

· Zeiss measuring machine for process control during the work phase.

· Processing even on small batches or unattended series.

.jpg)

.jpg)